Addressing the Elephant in the Pressroom: Legacy Flexo Pain Points

We’ve said it before and we’ll say it again – the 2200 is a workhorse. They’re great presses (if we do say so ourselves) that truly have stood the test of time. But what happens when capacity and space max out? Or the workforce struggles limit the amount of shifts that can be ran? Or waste costs become too much to ignore?

Print technology has exploded in the last decade. Automation, by way of servo and bearer plate technology, has unlocked massive potential for converters that comes in the form of savings. From productivity to waste to reliability, modern flexo is providing solutions to problems that converters didn’t even realize that they have.

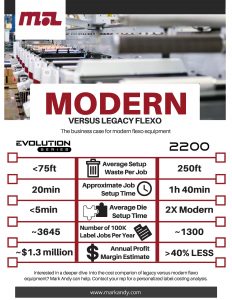

Take a look at the comparison below of modern flexo versus legacy flexo, more specifically Mark Andy’s brand new Evolution Series and our 2200, for a complete picture on the productivity and waste savings available with advanced technology.

Having close relationships with much of the market that has not yet found the need to modernize their pressrooms with servo-driven flexo equipment, we’ve found there are generally two camps. The first being “status quo”. These converters are generally happy with their business as-is, have no plans to grow their business. The second being those with budgetary concerns. Many think modern flexo is outside of the realm of possibility and continue to invest in proven technology. Some have the acquisition bug and are reluctant to spend capital dollars.

If you fall into the former – that’s a great place to be! We can all only hope to be so content in our business model. But if you are a part of the latter, you owe it to yourself to learn more about Mark Andy’s Evolution Series platform – a configurable, attainable full-servo flexo press. Submit your inquires for more information here.