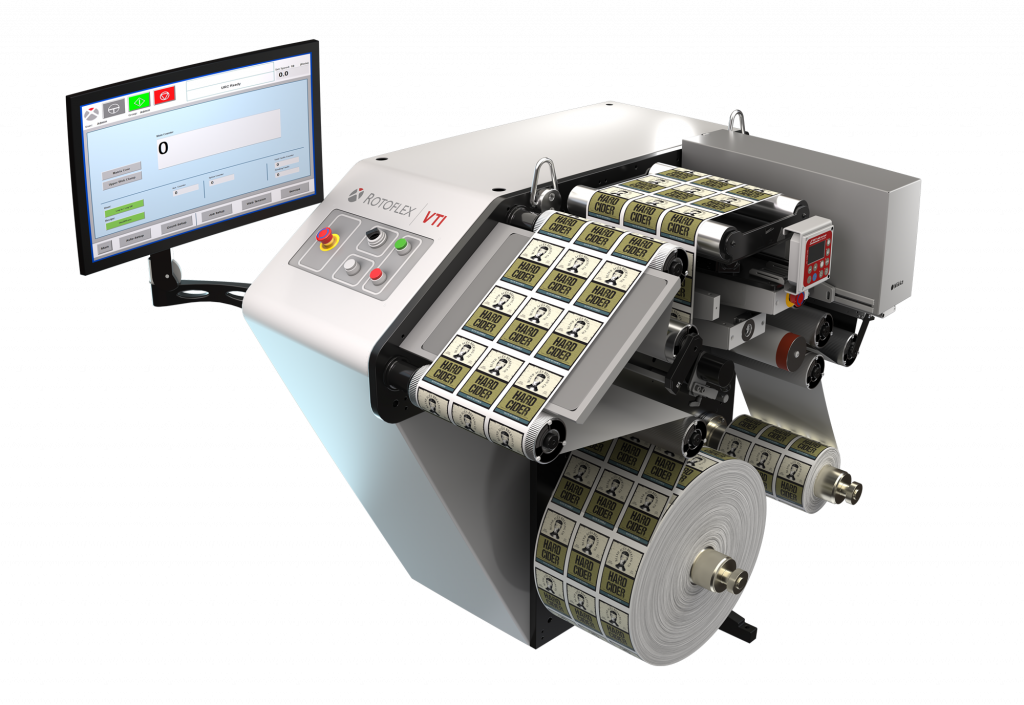

High-Speed Advanced Inspection and Rework at an Affordable Price

Re-inspection after fault correction ensures accurate final product

Optional inspection system for missing labels, splices, flags, spots, fading and missing color, text defects and registration

Optional 1D and 2D barcode reading, barcode grading, OCR, braille

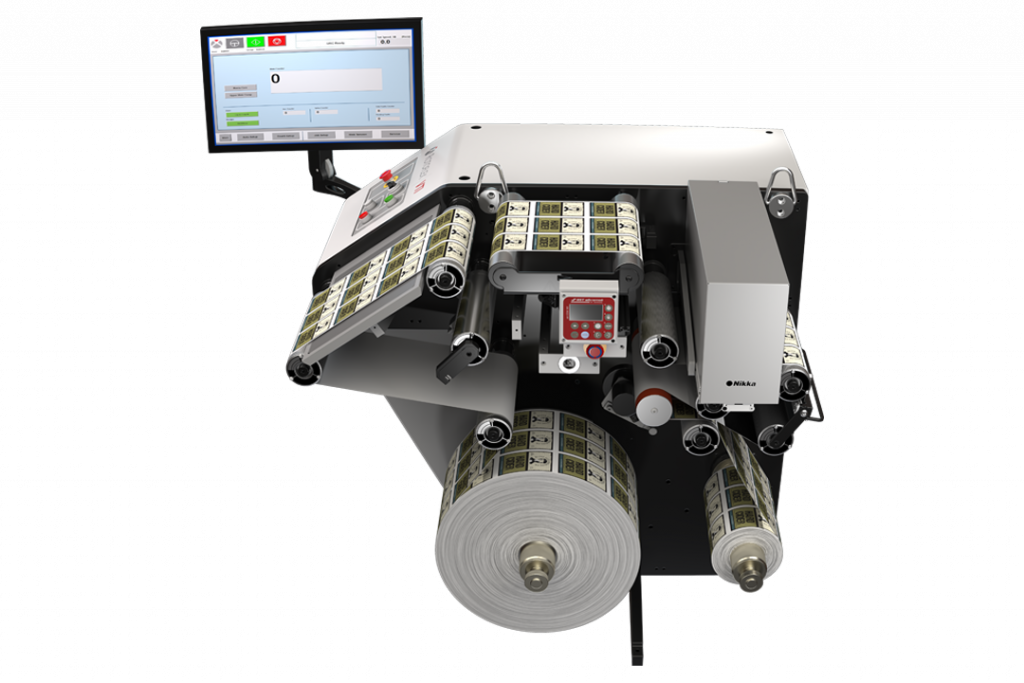

Ergonomically optimized for sit down operation

User-friendly operator interface with exclusive URC 2.0 and eDrive 2.0 control system

Compatible with multiple leading vision systems

Fault placement for accurate verification and correction

Supports both standard and pharma/security mode

VTI Features

Report management system

High performance processor

Most advanced defect detection system available

LINEAR - independent stream count

MMLD - 100% missing matrix and label detection

PRECISE faul placement at editing table

Automatic sensor calibration reduces set-up time and waste

Better use of power which results in better roll characteristics

Seamless roll quality at any speed and with any speed changes

Faster acceleration and deceleration with maximum control

Increase prodution effectiveness and preserves roll quality

Vision system selection is critical to ensuring accurate final product. Whether the application calls for 100%accurancy, variable data or braille inspection or barcode reading, the application design team at Rotoflex works closely with you to integrate the most advanced vision technology available to ensure a precise deliverable.

Technical Specifications

Web Width

10 inches (250 mm)

Max Speed (May vary with application)

750 fpm (228 mpm)

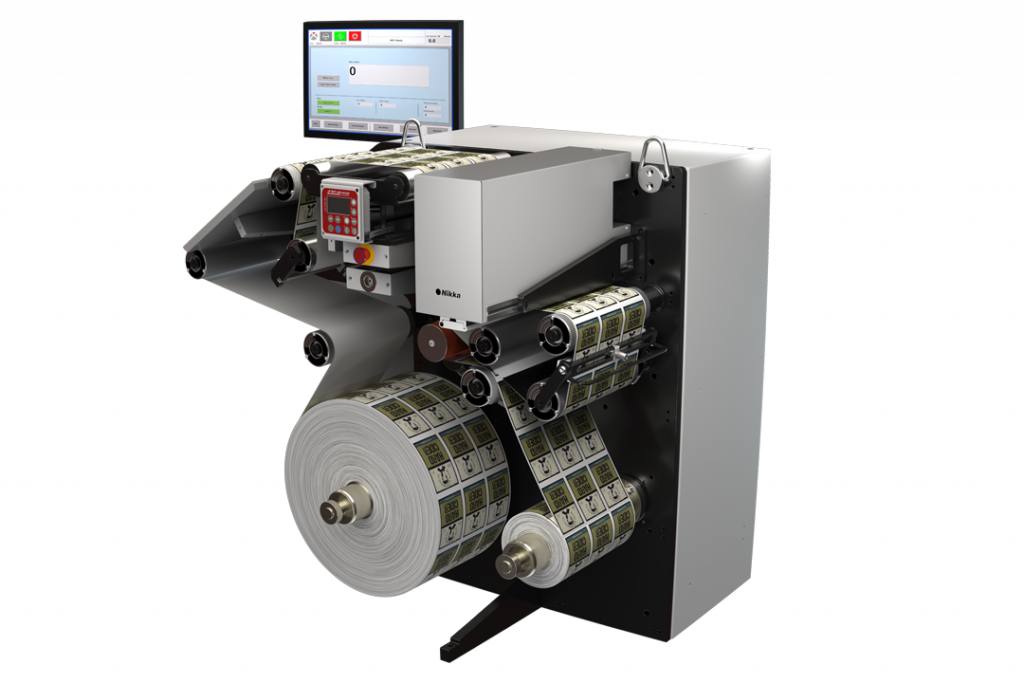

Unwind / Rewind Capacity

18 inches (457 mm)

Machine Dimensions (LxHxD)

44x42x43 inch (1120x1070x840mm)

Options

High intensity Strobe

Clear-on-Clear Label Count

Flag & Splice Detection

Matrix and Missing Label Detection

1D and 2D Barcode Reading, Barcode Grading, OCR, braille

Integrated Inkjet and Bar Coding Unit

Biometric Authentication (Fingerprint)

Report Management System (RMS)

Multilane Counter

Booklet Configuration