High Productivity Die Cutting

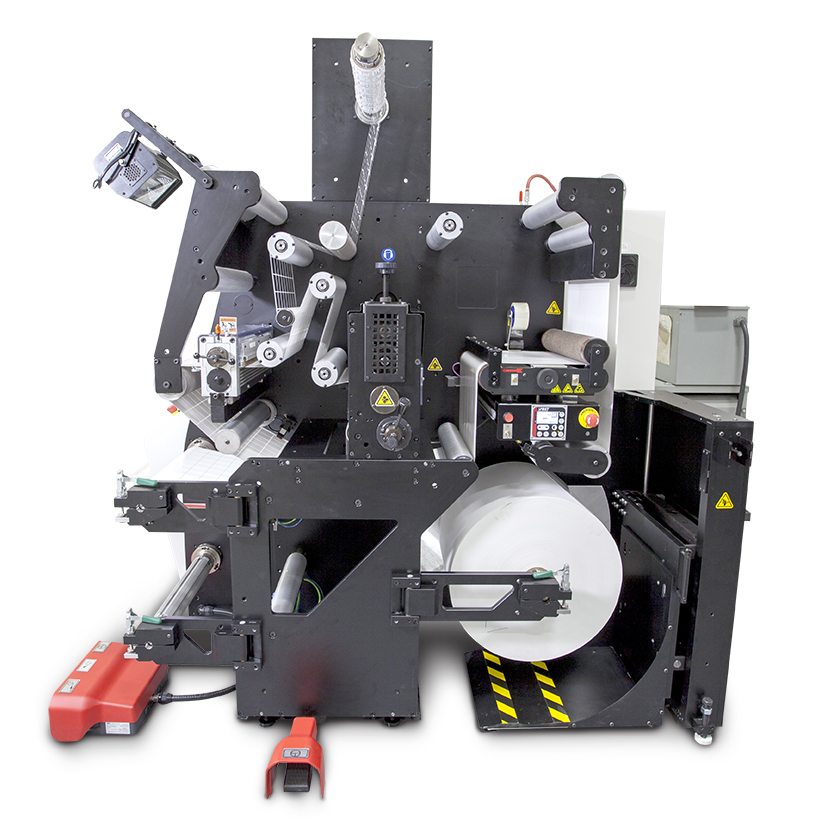

The Rotoflex DSI is the most efficient die cutting system available for today’s production environments. The dual purpose platform features precision die cutting or advanced roll and label inspection and interchanges easily. The DSI is ideal for any growing print shop and can be upgraded to meet future needs.

Report Management System (RMS) production analysis tool

High-performance processor

Most advanced defect detection system available

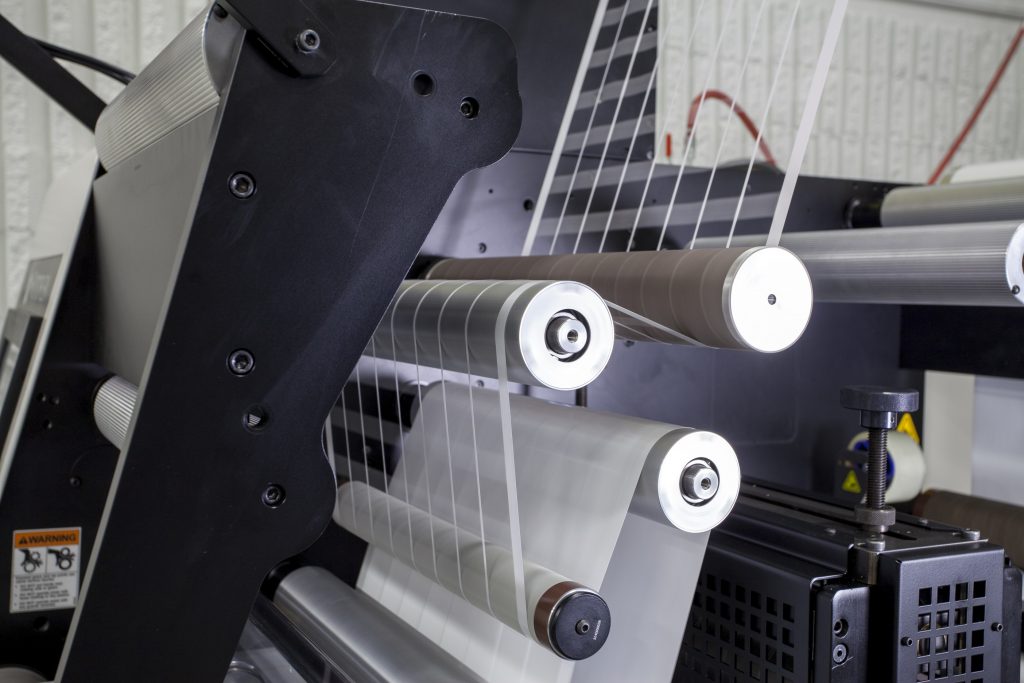

Linear – independent stream count

MMLD – 100% missing matrix and label detection

Precise fault placement at editing table

Automatic calibration reduces set-up time and waste

Better use of power which results in better roll characteristics

Seamless roll quality at any speed and with any speed changes

Faster acceleration and deceleration with maximum control

Increases production effectiveness and preserves roll quality

Witness the DSI in Full Force

The DSI series from Rotoflex is ideal for high-speed, accurate blank label die cutting. Available in 13.25 or 17.25 inch (330 or 440mm) widths, the DSI is a versatile, reliable die cutting solution for converters worldwide.

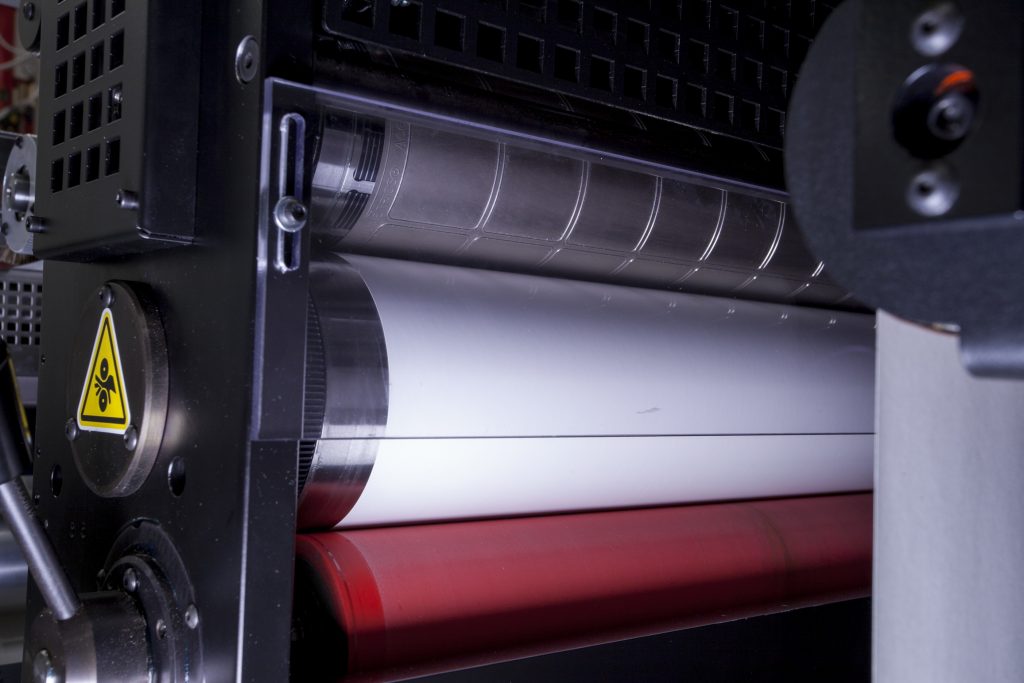

DSI Blank Label Die Cutting

This video demonstrates a DSI 440 (17 inch / 440mm) die cutting and inspecting 3 streams, delivering to 1 inch and 3 inch core shafts.

DSI Technical Specifications

Web Width

13.55 / 17.25 inch (330 / 440 mm)

Max Speed

Up to 1000 fpm (305 mpm) dependent on application

Unwind Capacity

28 inch (711 mm) or 40 inch (1016 mm)

Rewind Capacity

18 inch (457 mm) for single spindle machine

16 inch (406 mm) for dual spindle machine

Control System

Rotoflex URC 2.0

Drive System

Rotoflex eDrive 2.0

Inspection Options

Clear-on-Clear Label Count

Choice of Inspection Camera System

Matrix and Missing Label Detection

Flag & Splice Detection

High Intensity Strobe

Misc. Converting Options

Crush, Shear, or Razor Slitter

Slitter Cartridges

Anti Static Equipment

Roll Lift

Waste Wind-Up

Variable Data Printing

Ultrasonic Web Guide Sensor

Web Gripper-Feeder