Cut the Cost of Customization with Digital Hybrid Technology

We are in an age where variety is required, customization is key to product success, and SKU proliferation has taken over.

Retail marketers love complexity- it works for them because their product stands out on an overcrowded shelf. However, despite consumerism demanding the new and different every second of every day, experts are saying SKU proliferation and the option of variety is killing the bottom line for businesses everywhere, specifically those in the packaging industry- but, it doesn’t have to.

Several SKU variations of a craft beer label, printed on Mark Andy Digital Series

What Buyers Want- And What That Means For Labels

Buyers are demanding product variations because it makes them feel special. Offering several flavors, colors or low carb low sugar options creates a connection between the product and the end-user. It seems like that brand is connecting with them on a personal level, that this product was made “for me,” and buyers love that personalization. Despite the positive impact on consumers, manufacturers are running into problems. How do you forecast demand? How do you quantify the impact of product portfolios on your daily operations when your product portfolio is constantly changing? How does this affect the cost of materials such as labels or packaging?

Jennifer Dochstader, co-owner of LPC, Inc, and co-chair of this year’s Digital Packaging Summit, spoke at the event about market changes in the packaging industry and how those changes are impacting label and packaging providers. One very real concern converters have when considering printing technology is that of constantly changing product labels- whether those modifications arise out of new marketing initiatives or changes to compliance standards for food packaging. Dochstader spoke about the fear of printed packaging becoming obsolete, sitting usable in storerooms due to these constant changes.

Customization Is Unavoidable

Let’s face it, changing promotions that lead to a change in label design are inevitable given the current customization trend today. There’s no way to avoid SKU proliferation if you want to stay competitive or expand into new markets. But to a supply manager, complex SKUs mean an increase in raw materials and consumables. Companies are finding themselves unable to make informed decisions about how much product to make, which trickles down into packaging needs.

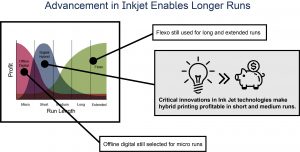

That’s where true hybrid technology comes into play. Inline hybrid technology takes the stress out of over or under forecasting with profitable short and mid-run capabilities. Mark Andy’s fleet of dedicated hybrid options offers the ability to cut your bottom line and keep in line with your marketing goals with the option of versioning and customization through variable data printing (VDP).

So what is versioning? It’s almost as simple as it sounds- the ability to print several versions of the same label, like when a product comes in a slew of different flavors. The basic components of the label stay the same, but the color or wording, or artwork may change. Instead of printing several small runs of a new label each time you need it, digital hybrid technology allows you to print versioned labels in the same pass, all in-line. Customization is a similar process. Think of Snickers Bars campaign “You’re Not You When You’re Hungry.” Each candy bar wrapper is personalized to say something different like “Hot Mess” or “Grumpy.” Again, something easily attained through digital production means, and more specifically something you can accomplish with Mark Andy’s true hybrid line of presses.

True Hybrid Closes the Forecasting Gap

Digital One, an entry-level fully digital inline press, combines affordability with digital output capabilities perfect for “craft and cotton industries” looking to stay on trend with custom label options. Digital Series, a digital hybrid workhorse marrying the best of flexo and digital in one machine, is another option better suited for mid to large-scale label makers looking to profitably produce versioned SKUs without the headache of several different job runs. The Digital Series modular design and combination of highly configurable in-line converting and finishing with high-quality digital printing offers decorative solutions as well, such as flexo stations for top coating, metallics, and cold foil. This means not only can you print several SKUs and product variations, but you can do so with style! There is no need to shy away from SKU proliferation when you have the full production capabilities of Mark Andy’s true hybrid technology.

Changing market trends in the packaging industries can be intimidating. Label makers and brand owners can have a hard time grasping how to keep their forecasting on track while keeping up with the need for customized product packaging based on region, time of year, or even a change in compliance standards. With the flexibility of digital hybrid technology, those frustrations are a thing of the past. Producing quality labels using versioning and customization along with inline decoration and finishing is easily managed on Mark Andy’s fleet of hybrid presses. True hybrid technology is the future of print, and with partnering with Mark Andy for your digital needs is the perfect solution to staying on trend with retail consumerism and customization in label making.