Repacorp Printing House: A Comprehensive RFID Label & Tag Production Partnership

Growing interest in RFID-based solutions

“Any customer that has a need to eliminate human error has a reason to use RFID,” says Rochelle L. Heinl, Vice President, Repacorp Inc., the North American printing house that invested in this technology 15 years ago. The company is able to successfully offer its customers a variety of new innovative label solutions as well as other RFID-based products. Since the beginning, Repacorp centered their RFID production on advanced narrow-web printing presses from Mark Andy.

“RFID seems to finally be picking up,” notes Heinl, “the interest in this product line has peaked over the last year and I believe customers seem less scared and more understanding of the technology allowing for a greater overall adaption.” Recently, big retail shops have widely implemented this technology, which equated to considerable growth for Repacorp, delivering RFID-based labels to many retail companies.

The printing house has cooperated with many brand owners in the area, but its RFID solutions have also been used by companies from other industries, including automotive, race-timing, healthcare, and warehouse tracking to name a few. “There are many different applications of this technology. One of our customers using RFID in their warehouse to help with inventory consistency and counts. They were able to cut down their warehouse staff from 6 employees to 2 and increase the accuracy of items on the shelf to over 98 percent, up from 81 percent,” Heinl continues.

Automated operations, enhanced product offerings

As Heinl indicates, users of RFID technology mainly appreciate its ability to eliminate human errors: “The accuracy and consistency of any project can be greatly increased because of RFID. For example, specific to retail inventory control, when shoppers go into a store to get a specific item, if that item is in stock, but not in its designated location, consumers are less likely to spend additional funds and will think about the lack of product next time they go to buy a similar item, and likely may consider another store. With RFID technology, if the clerk is not able to locate the product on the shelf, however, an RFID app showing them where it was last scanned allows the item to be tracked down and purchased.”

Repacorp is using RFID technology in their own warehouse, which makes inventory tracking simpler and more convenient. “RFID helps in fast locating of any batch of printed labels,” states Heinl.

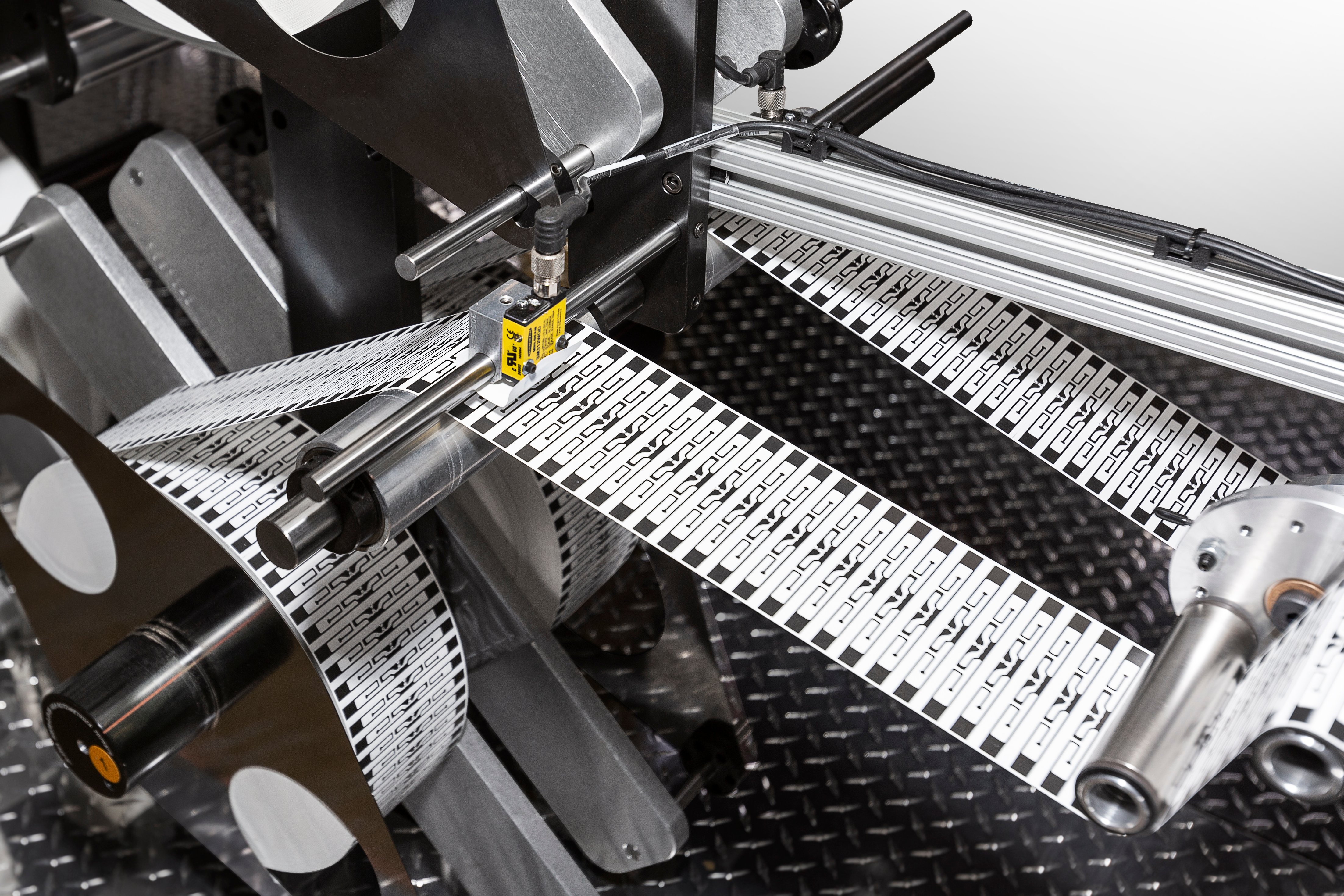

The converter has a very diverse product offering. It includes labels (from blank to premium) printed in flexo and digital, as well as shrink sleeves and flexible packaging. “Repacorp has the equipment that allows us to do the most output of imprinted/encoded labels in the industry,” Heinl emphasizes. She continues, “Our innovative presses enable us to take either a database provided by a customer or a series of numbers and quickly convert to meet a customer’s enlarging need of product. As the need for pre-numbered labels grows in the industry, Repacorp would be a great partner to supply the product for this.”

A long-term partnership with Mark Andy

Repacorp has partnered with Mark Andy to purchase high-quality capital equipment for nearly since its incorporation. Heinl elaborates, “Mark Andy’s solutions, with integrated RFID modules, have been configured according to our needs and Mark Andy has been an incredible partner for all our product lines. From the shrink industry to RFID, Mark Andy has been a great support. They have worked extremely diligently alongside of different suppliers helping us establish and create truly magnificent pieces of equipment. Currently, due to this partnership, we are one of the leading RFID converters in the marketplace.”

Rochelle L. Heinl, Vice President, Repacorp Inc. provides valuable insight into RFID applications and discusses their production on their Mark Andy Performance Series P7

Repacorp started manufacturing RFID labels and tags in the mid-2000s. Since that time, the company installed four presses from Mark Andy. In describing the scale of their production capabilities, Heinl explains, “We can now convert 10”– 20” web, print front and or back up to 8 colors. We insert, die cut and verify all inline and can print and encode multiple lanes across at high speeds while also checking for duplicates. Our diverse equipment platform allows us to tackle the simplest to most difficult RFID projects.”

”RFID adoption is growing. In today’s world, many companies are looking at how to automate any operation within their facility, and, a great way to help achieve that is through using RFID technology,” Heinl concludes.