Preventive Maintenance: The Secret Ingredient for Success

Imagine buying a brand-new car and never taking the time to get its oil changed, ultimately leading to the entire engine shutting down and having to be replaced. Something as simple and easy as getting a car inspected by a mechanic every few months keeps it running for hundreds of thousands of miles.

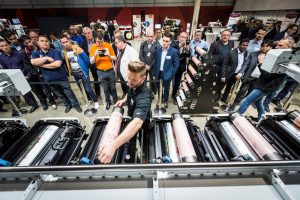

The same concept applies to pressroom equipment. Investing in high quality machinery is essential to a company’s success, but many business owners or production managers fail to place the same level importance on maintaining their machinery. Don’t fall victim.

By making preventive maintenance a priority for pressroom equipment, you win big. Following are four reasons how your printing operation can save time and money with reduced downtime and improved customer loyalty.

Extend the Life of Your Equipment

Preventive maintenance (PM) programs are designed to preserve and restore equipment reliability before the unit has the opportunity to fail. Not only does preventive maintenance extend the life of your asset, it enables higher degree of performance and premium quality output. Printing companies that take the time to maintain their equipment regularly ensure that they are getting the best performance possible out of their machines for as long as possible.

Reduce Downtime

Equipment performance goes hand-in-hand with profitability. If printing presses go down, so do incoming dollars that impact your bottom-line. The main goal of preventive maintenance is to avoid or mitigate the consequences of equipment failure. Incorporating PM activities into your workflow reduces the likelihood of extended downtime, meaning more rolls of finished product out the door. When presses are running efficiently and effectively, the more profit a company can make.

Enhance Customer Service and Reputation

PM initiatives support every converter’s mission to provide customers with superior service. Many customers are just as interested in the reliability of services as the quality of the product they are receiving. Regularly scheduled upkeep enhances equipment functionality and companies that practice it can offer their customers more reliable service. Consumers seek out and stay loyal to companies that can provide them with quality products and reliable service. Businesses who realize this are the well-positioned for growth.

Plan for Future Part Replacements

When companies plan for equipment to be serviced at specified periods of time, employees can record equipment deterioration. If there are issues, the parts of the press in question can then be replaced before they cause a system failure. Understanding when a part needs to be replaced enables better forecasting expenses and minimizes the risk of surprise expenses in the future. When it is time to replace a part, replacing with an OEM part will guarantee the best performance out of your machine. This saves a company a great deal of money and hassle.

Final Thoughts

Investing a small amount of money and time into regularly scheduled preventive maintenance on equipment now, can save the company from massive amounts of time and money lost in the future. The Mark Andy Service Team is dedicated to keeping quality equipment running at maximum performance levels. To support the importance of preventive maintenance, Mark Andy offers multiple service packages based on your company’s level of service required.