Boosting Revenue with Hybrid Printing and Inline Converting

With the overall success of digital printing, most conventional label and packaging printers are moving forward with plans to integrate digital hybrid options to their already robust flexographic workflows. Hybrid presses can be described as standalone print devices that feature a digital print engine and flexo print stations, utilizing the advantages of both printing processes while delivering labelling options that accommodate any job. Mark Andy recently partnered with packagePRINTING to produce an educational webinar exploring the key benefits of digital hybrid print solutions.

Bob Leahy of Keypoint Intelligence- Info Trends, and Gene Kubicki of Tabco, Inc., discuss how hybrid printing and in-line converting solutions can push a brand forward and increase revenue.

Bob Leahy

When discussing the benefits of switching to a digital hybrid press, Leahy brings many key points to the conversation. Not only are hybrid presses cutting cost for converters, but they also allow flexo print providers considering adding digital capability the opportunity to stay current with market trends and meet the demands of their clients.

According to Leahy, there are two classifications of digital hybrid presses- dedicated hybrid and retrofit hybrid. A dedicated hybrid press is one that is built from the ground up to be a comprehensive, multi-process printing unit. The second, a retrofit hybrid solution, means adding a CMYK module to an existing press and can be a great option for combining two approaches.

Leahy continues, discussing the advantages and differentiators of each print solution within Mark Andy’s digital portfolio

Full-Production Hybrid Workhorses

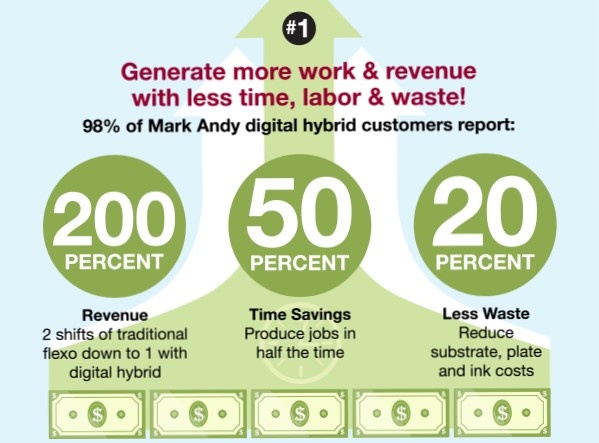

The Mark Andy Digital Series full production press gives converters the option to customize their machine with the flexibility of both digital and flexographic technology. Modularity is a large part of what makes hybrids of this kind a great option for converters. With the option to have flexographic stations positioned both before and after the digital print module, label printers can can truly have the best of both worlds when using Digital Series.The Digital Series is, in Leahy’s opinion, the top of the line when speaking of digital hybrids. With a high-output hybrid press, an entire job is completed in a single pass- from decoration to digital print, cutting to finishing. Simply put, it allows you to produce more with less time, waste, and energy.

Flexible Retrofit Solutions

The Digital +3600, part of the Mark Andy Digital Plus Program, is unique in that it can be fitted onto any legacy Mark Andy press, like the 2200. This machine can also be retrofitted onto any other traditional narrow-web press. The Digital +3600 offers high resolution digital options for converters who are not ready to invest in a full machine.

Entry-Level Digital Hybrid Presses

The Digital One is the 3rd leg of Mark Andy’s digital strategy. The Digital One is the first press of its kind and is a standalone digital option ideal for those just getting started with a hybrid solution. The entry-level printing and converting platform uses a CMYK dry-toner digital engine and provides label-enhancing decoration options, such as varnishing, spot colors, or cold foil.

Leahy firmly believes that flexo press suppliers understand that digital is here and is a necessity to following current label and packaging market trends. Digital offers several advantages, such as quicker lead times, VDP, and versioned graphics for shorter run lengths while maintaining profitability.

Gene Kubicki

Kubicki is also quick to point out the advantages of digital hybrid technology. Tabco has always been a technology-centric company, striving to adopt new technologies as closely to their release as possible. With that being said, Kubicki became aware of hybrid technology far before he made the decision to move forward with purchasing a Mark Andy Digital Series press. Ultimately, having experience with the Mark Andy brand along with his knowledge of their support team, and Mark Andy’s ability to be the sole supplier of flexo and digital converting equipment swayed Kubicki to finally purchase the Digital Series. After the switch, set-up was a breeze and Tabco employees required very little training due to their previous work with the Performance Series flexo platform which the Digital Series is based upon.

A Whole New Workflow

Kubicki goes on to discuss how switching to a digital hybrid press has changed the complete company workflow for Tabco. Kubicki describes the hybrid platform as being a flexo press enhanced with digital capabilities. This is especially helpful for Tabco because it allows them to split the function of their Digital Series press based on job mix. Tabco uses this flexibility to their advantage by running the machine as both a flexo and digital press. The multi-use functionality of their Digital Series press enables the company to run their digital jobs during first shift and flexo jobs during the second.

Absolute Profitability

The switch to a digital hybrid has been a profitable one for Tabco. Increased productivity and time savings has allowed coverage of prepress costs in their selling price. Customers of Tabco love it because ancillary charges, such as plate or rush fees, have been greatly reduced by switching to digital, Kubicki says.

Kubicki embellishes on some of his favorite key features of adopting a digital technology. According to the owner, trapping is almost non-existent, artwork is easier to prep, and a large number of job changes can be made press-side.

Final Thoughts

Consumers want products fit to their unique lifestyles, which means higher demand towards short-run work. The market is changing and customers are starting to ask about digital technology. Many converters are beginning to see the numerous benefits associated with adding digital technology to their flexo options. With short runs becoming more and more popular, digital hybrids are becoming a necessity for converters today

To access the complete webinar free on-demand, follow this link.